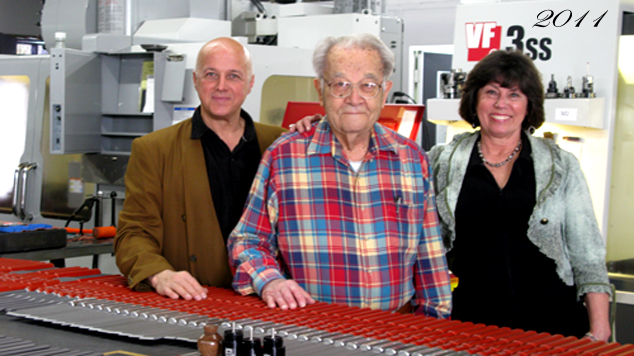

Glaser Hitec Engineering is the second generation of a company started by worldwide known engineer, woodturner and toolmaker Mr. Jerry Glaser, which was both far-reaching and visionary in the wood turning community. Jerry was following a dream when he produced the finest wood turning tools the world had ever known. For over half a century, Glaser tools are legendary for their edge holding, quality of construction and ability to outlast any other turning tool.

Today, Glaser Hitec Engineering lives on. Not only we continue Jerry’s Legacy, but we constantly work on developing and introducing new concepts and new tools, such as the miniGlaser QR system and the upcoming Synergy Ultragouge.

Glaser Hitec Engineering is totally committed to serving the wood turning community with the highest quality products and the most innovative designs in woodturning tools.

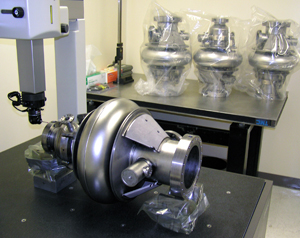

Our products are manufactured by Advanced Theoretical Concepts, Inc. Our west coast facility is located in Camarillo, California. It showcases 10,000 square feet of state of the art HAAS CNC equipment. For the past 30 years, ATC has been a leader in the development and engineering of precision components for the United States Military, aerospace and Deep Space Exploration, using the latest technology in digital systems, computer-aided design and state-of-the-art automation. Currently we are heavily involved in the manufacturing of components for the new Mars 2024 mission with Jet Propulsion Laboratories and the International Space Station with Northrop. ATC has been involved in three Mars Missions.

Our products are manufactured by Advanced Theoretical Concepts, Inc. Our west coast facility is located in Camarillo, California. It showcases 10,000 square feet of state of the art HAAS CNC equipment. For the past 30 years, ATC has been a leader in the development and engineering of precision components for the United States Military, aerospace and Deep Space Exploration, using the latest technology in digital systems, computer-aided design and state-of-the-art automation. Currently we are heavily involved in the manufacturing of components for the new Mars 2024 mission with Jet Propulsion Laboratories and the International Space Station with Northrop. ATC has been involved in three Mars Missions.

Through the years, ATC has developed stringent criteria of quality assurances in order to provide parts that are accurate and true to print, which in turn reduces cost and increases customer satisfaction. We now apply the same stringent criteria to the production of our woodturning tools and accessories. These implemented procedures only cement the already established methods that Jerry Glaser has developed throughout the years. We strive to provide high-quality parts. That’s how we are able to deliver state of the art woodturning tools.

Through the years, ATC has developed stringent criteria of quality assurances in order to provide parts that are accurate and true to print, which in turn reduces cost and increases customer satisfaction. We now apply the same stringent criteria to the production of our woodturning tools and accessories. These implemented procedures only cement the already established methods that Jerry Glaser has developed throughout the years. We strive to provide high-quality parts. That’s how we are able to deliver state of the art woodturning tools.

The adoption of HAAS CNC centers was a calculated move for the development of our tools and also to attend the quality and precision demands of our aerospace customers. HAAS Automation is a strategic partner and it has propelled our facility to completely new quality level.