[dropcapcircle] A [/dropcapcircle]lways remember that a system which showcases the highest tolerances in the world today, requires proper care. Like any precision instrument, one must pay attention to debris and deposits which could prevent the functionality of the system

It is strongly recommended that BEFORE you use the system, you inspect inside the receiving adapter to make sure there are NO obstructions or dirt inside which could prevent the total engagement of the stainless steel spheres in their proper pockets.

ALWAYS make sure that after you engage the tool the sleeve is completely close at the edge and it shows NO GAP.

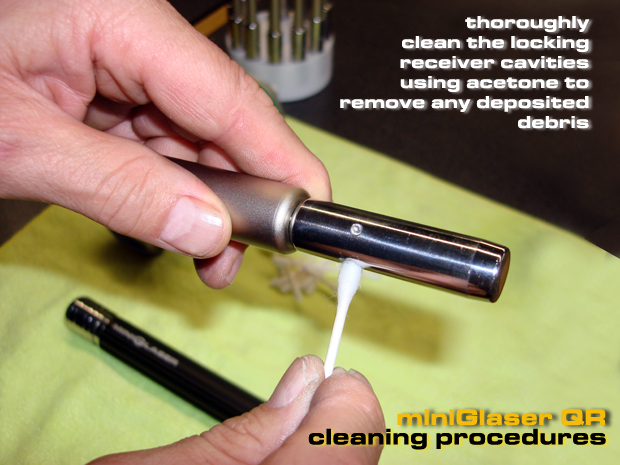

After using the system we recommend that you thoroughly clean it.

We have created this small sequence for you to see how we clean our tools. Following this protocol will ensure that your system lasts and performs for many years, giving you the pleasure of portability and performance.

If you have any questions, feel free to drop me a line and I will more than happy to go over the procedures with you.

Enjoy!

Paulo Marin